The Strengths That Support Our Value Creation

Creating Value through the Constant Enhancement of Technologies and Understanding of Market Needs

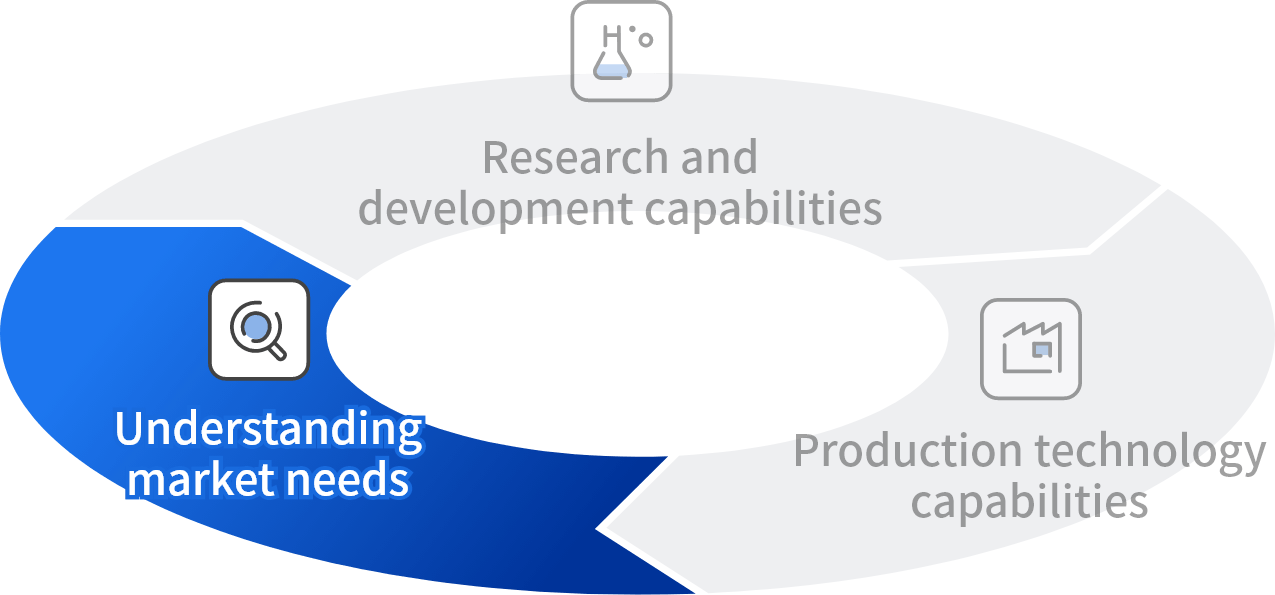

Understanding Market Needs

By effective utilization of the underlying and core technologies we have accumulated over a century,

and a thorough understanding of market needs, we have made further progress in product development,

technological improvement, and market development

Use of our core technologies and our understanding of market needs has enabled our products to continue evolving. As a result of this constant evolution, we have developed new products, improved technologies for our existing products, and developed new peripheral markets.

In April 2021, we consolidated and integrated the operations of the Odawara Research Center and the Chiba Research Center. The Odawara Research Center is now in charge of both research and development for agrochemicals, as well as research and development of chemicals for functional and electronic materials.

For the development of agrochemicals, we have a research structure in place to advance every process from basic research to field experiments. One of our major strengths is our ability to carry out highly efficient and swift research and development, and product development that combines evaluation and research. For chemical development, we have created a structure that enables us to undertake everything from the development and commercialization of functional chemical products using our proprietary technologies, to research on improvements and rationalization.

Looking ahead, we will reinforce collaboration between our marketing, technology, service, manufacturing, and other departments to further improve our research and development structure.

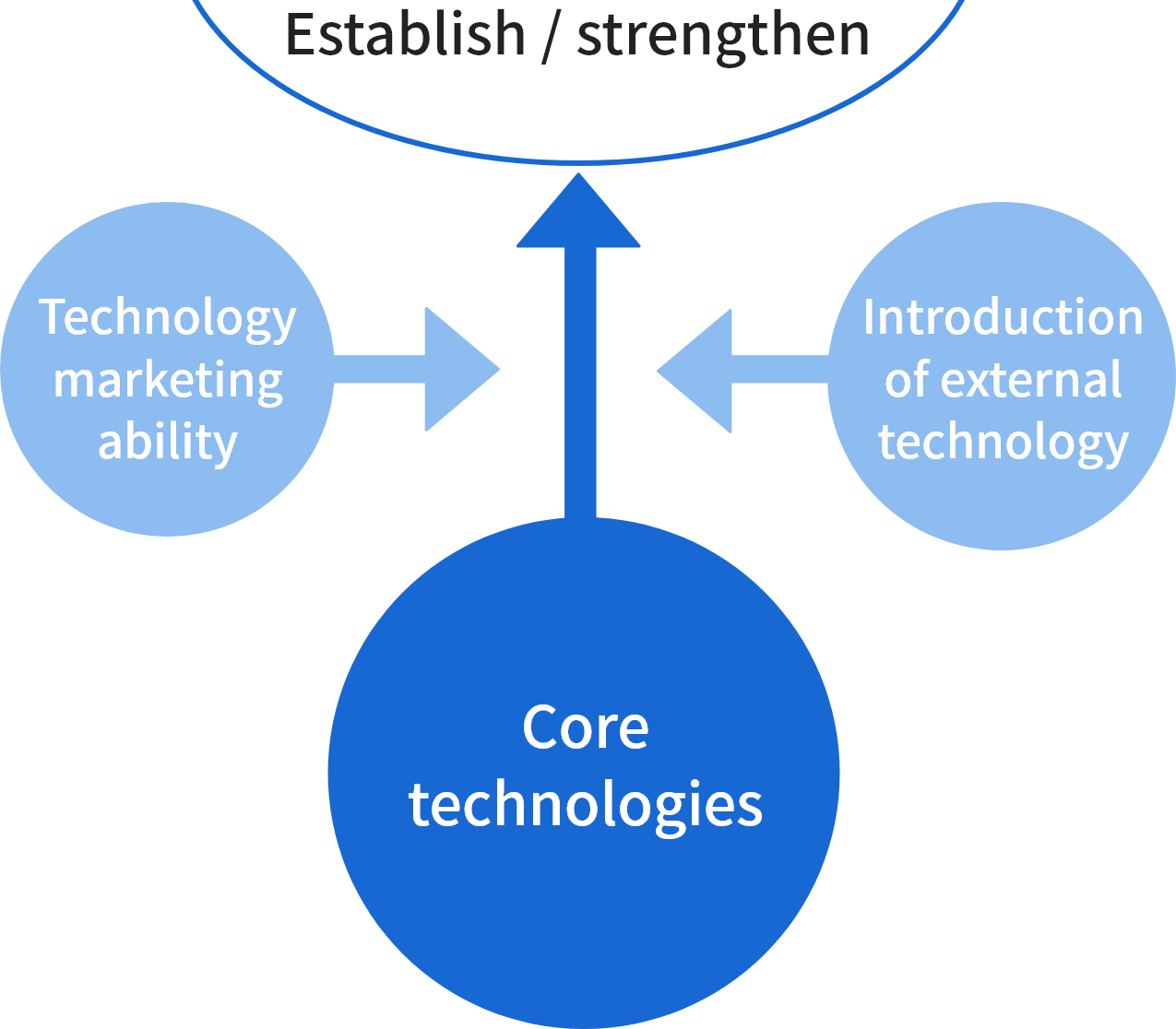

Establishing and Strengthening Core Technologies to Bolster Existing Businesses and Create New Businesses

The Nippon Soda Group possesses many excellent core technologies. However, when considering future market needs and changes in the social environment, it is essential to introduce new technologies, as well as to establish and further strengthen core technologies. Therefore, we will strengthen our technology marketing abilities, broaden our assessment and understanding of new needs, and establish a system that can respond more flexibly.

By collecting information from various chemical markets, analyzing technological trends in each field, and examining solutions that cater to needs brought about by social change, we are unearthing new possibilities while staying alert to trends in even more areas. For example, we examine whether or not there are any aspects of commercially available products that can be substituted by the Group’s technology. On top of that, we will create new value by improving and increasing the sophistication of our proprietary technologies, and by developing new technologies while cooperating with external parties.

Understanding Market Needs through Attentive Response

The Cellulose Technical Application Center (CTAC), which we opened inside the Chiba Research Center in October 2019, functions as a facility for creative collaboration alongside our customers. In addition to offering technical seminars and live online training programs at CTAC, we also respond to diverse requests for our products, including NISSO HPC.

At the Nippon Soda Group, be it at CTAC or any other facility or situation, we carefully listen to our customers to understand market needs while ensuring attentive customer response. We are linking these efforts to the development of new solutions. Ultimately, it is enhanced communication with our customers and the creation of trustworthy relationships that leads to the further evolution of our products.

Responding to Market Needs

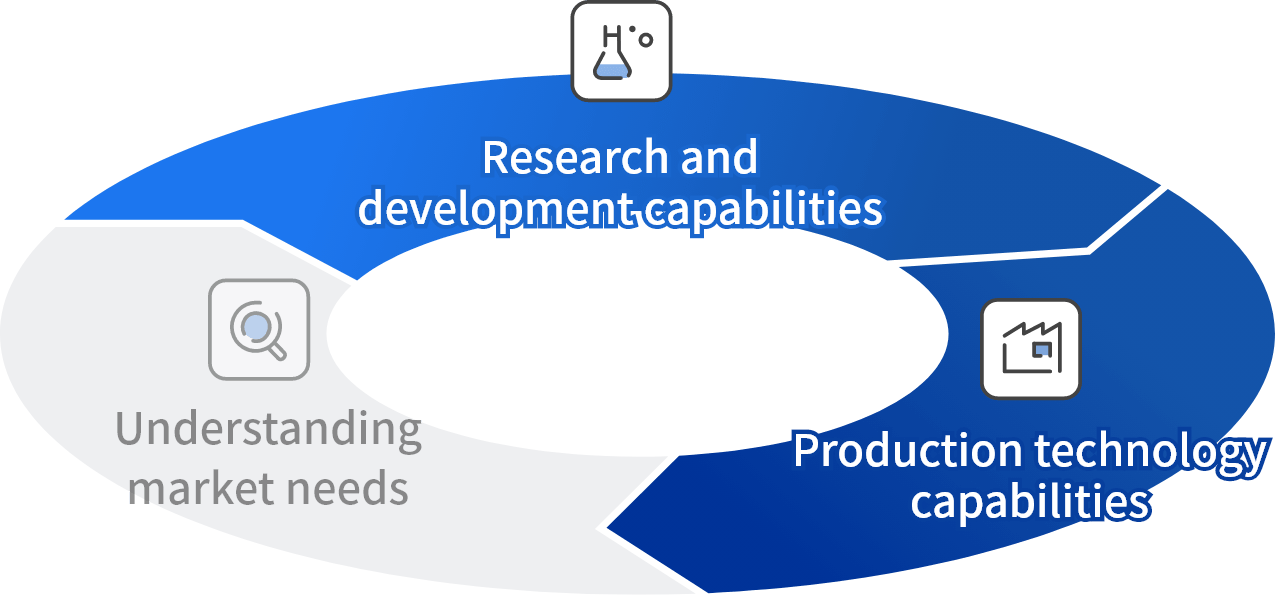

Through improvement of the research and development and production technology capabilities we have accumulated over a century,

we have created a safe, secure, stable production system that is highly efficient

At our production technology research centers, which we have in place at each of our plants, we are engaged in diverse technological development and engineering research. Our strengths lie in our ability to work with our research departments to develop highly productive proprietary manufacturing technologies.

Beginning in 2019, we have been working to build a system that enables efficient use of experimental equipment and human resources engaged in research. Furthermore, a new research building that consolidates and integrates research facilities at the Takaoka Plant and the Nihongi Plant is scheduled for completion in 2022. The Nippon Soda Group is also accelerating product development by strengthening synergies with manufacturing process know-how and manufacturing know-how, and by improving operational efficiency.

To respond to market needs, it is essential that we combine the research and development capabilities that allow us to continuously improve on our effective products with the production technology capabilities that deliver leading niche products to our customers safely. With safety and security our foremost priority, we are working to make continuous improvements to our production technologies and in turn build an even better production structure.

Accelerating R&D Using External Technologies

In creating new businesses, open innovation is key—that is, making use of not only internal resources, but also external research resources and technologies. At Nippon Soda, we are promoting open innovation through collaborations with external institutions in industrial and academic circles.

| Themes | Progress, Results and Outlook |

Nippon Soda’s Strengths |

|---|---|---|

| Development of a new porous material with a metal-organic framework (MOF) (An industry-academia collaboration project with Prof. Mao Minoura and his research team from the Chemistry Department of the College of Science at Rikkyo University) |

|

Synthesis technologies accumulated through our development of agrochemicals, and production technologies |

| Development of a platinum-tungsten solid solution alloy nanoparticles (Joint research with Prof. Hiroshi Kitagawa and his research team from the Graduate School of Science, Kyoto University) |

|

Processing technologies to particulate and dispersed metals |

| Development of a new compound for thermally activated delayed fluorescence (TADF) material, a next-generation organic electroluminescence material (Joint development with Kyulux, Inc.) |

|

Long-accumulated, advanced organic material development capabilities and synthesis know-how |

We are currently using artificial intelligence and machine learning to enhance the efficiency of our research and development and speed up our development of new products. We are also moving forward with digital transformations to ensure even safer, more stable production.

In research and development, our AI working group is leading efforts to reinforce our data science capabilities and introduce materials and process informatics. In doing so, the aim is to create a structure that facilitates even more efficient R&D.

In production technology, we are working to streamline work processes, reduce labor, and create mechanisms for safe, stable operations. We are also developing AI-proficient personnel who can lead these efforts. In the future, the aim is to further streamline production and reduce the manpower required.