Working to Achieve a Sustainable Society

Toward a resource

recycling society

The Nippon Soda Group’s Efforts

to Reduce Its Environmental Impact

The Nippon Soda Group sees environmental issues such as climate change and biodiversity to be among the most important challenges facing the international community.

As society and industrial structures undergo drastic changes to address these issues, we are working to solve social problems through chemistry and related services, while cooperating with local communities to promote environmental conservation efforts.

Our Group promotes “Responsible Care Activities”, business activities that are conducted while voluntarily taking steps to ensure the environment, safety, and health in all processes ranging from development, manufacturing, distribution, use, and final consumption through to disposal and recycling.

In addition, by providing a variety of products and services based on our long-accumulated technologies for detoxification and safety of industrial waste, heavy metal removal, resource recycling, and water treatment, we are contributing to the formation of a recycling-oriented society through the prevention of environmental pollution, recovery and recycling of industrial waste, and effective use of water resources, as well as research and development for the early social implementation of next-generation energy with reduced environmental impact in cooperation with external organizations.

Furthermore, we are contributing to the preservation of biodiversity by working with local communities to cultivate forests that absorb CO2 and water source protection forests, and by engaging in sustainable plant conservation to protect pine and cherry trees from pests.

We will continue to engage in such environmental conservation efforts to minimize the impact that our business activities have on the environment, while creating new value through the power of chemistry and continuously developing our business in order to realize a sustainable society and increase our corporate value.

Achieving Carbon Neutrality

In April 2022, the Nippon Soda Group established the Greenhouse Gas Emission Reduction Working Group to work across the organization with the goal of achieving carbon neutrality by the year 2050 and aiming to reduce greenhouse gas emissions by at least 30% compared to 2013 levels by 2030. With our endorsement of the TCFD Recommendations in September 2022, we made public the Group’s initiatives in the four categories of “Governance”, “Strategy”, “Risk Management”, and “Metrics & Targets”. We are also active participants in the “Carbon Neutrality Action Plan” spearheaded by the Japan Business Federation (Keidanren), taking steps to reduce CO2 emissions and promote energy conservation.

Specifically, we will switch to non-fossil energy sources and promote the use of renewable energy for the caustic soda electrolysis equipment used at the Takaoka Plant (Toyama Prefecture), the Group’s largest user of electricity, and are aiming to improve energy consumption per unit of production by replacing manufacturing equipment with more resource- and energy-efficient equipment. Furthermore, we have launched our Logistics Improvement Project, which promotes the reduction of energy consumption by reviewing logistics within workplaces and shortening flow lines.

As part of our efforts that span the entire supply chain, we are working to achieve carbon neutrality by calculating not only greenhouse gas emissions from our own activities (Scope 1 & 2) but also indirect emissions outside the scope of our activities (Scope 3) with reference to guidelines such as the “Basic Guidelines for Calculating Greenhouse Gas Emissions through Supply Chains” issued by the Ministry of the Environment.

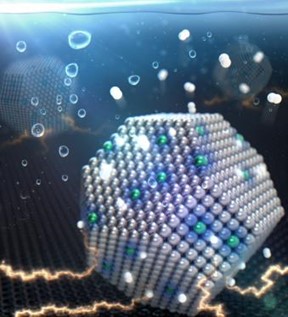

In the field of R&D, we are working with Kyoto University on the development of highly active hydrogen-evolving electrocatalysts based on novel platinum-tungsten solid-solution alloy nanoparticles. The hydrogen evolution reaction (HER) by water electrolysis using this solid-solution alloy has dramatically improved the hydrogen generation efficiency. Moving forward, its development as an HER catalyst will be accelerated, and its social implementation as a hydrogen production catalyst will enable more efficient production of hydrogen, a clean fuel, and thus has the potential to contribute to the realization of a safe and environmentally minded society.

Depiction of hydrogen gas generation via platinum-tungsten solid-solution alloy nanoparticles to which overvoltage is applied.

As a corporate group, we own approximately 56 hectares of land in Hamamatsu City, Shizuoka Prefecture, which has acquired Forest Stewardship Council certification (a forest certified as having appropriate management systems in place for forest conservation). To mark the 100th anniversary of our founding, we also established the Nippon Soda Group Forest within the Joetsu Kuwadori Community Forest in Joetsu City, Niigata Prefecture, the birthplace of our company, and have since continued to make donations to the National Land Afforestation Promotion Organization to help create biodiverse forests and preserve the environment.

Focus on Development of Low-Risk Pesticides and Biological Pesticides

The Nippon Soda Group has been promoting R&D and sales expansion in the global market, mainly for our chemical pesticides. However, in recent years, along with increased awareness of the environment, there has been a growing demand for reduced pesticide use as well as biological pesticides in order to reduce the impact on the ecosystem.

In response to these evolving trends, our Group is working on R&D and sales expansion of biological pesticides and strengthening our systems to prepare for our deployment into the field of smart agriculture.

In Japan, in accordance with the “Strategy for Sustainable Food Systems” formulated by the Ministry of Agriculture, Forestry and Fisheries, we are focusing on the search for low-risk pesticides, development of biological pesticides and biostimulants, expansion of IPM (Integrated Pest and Weed Management), and development and registration of pesticides for drone-based spraying utilizing ICT.